General Content:

1/Components of Aerospace Plastic Injection Mold

2/Why Choose Aerospace Plastic Injection Mold?

3/Differences Between Aviation Equipment Injection Molds & Ordinary Injection Molds

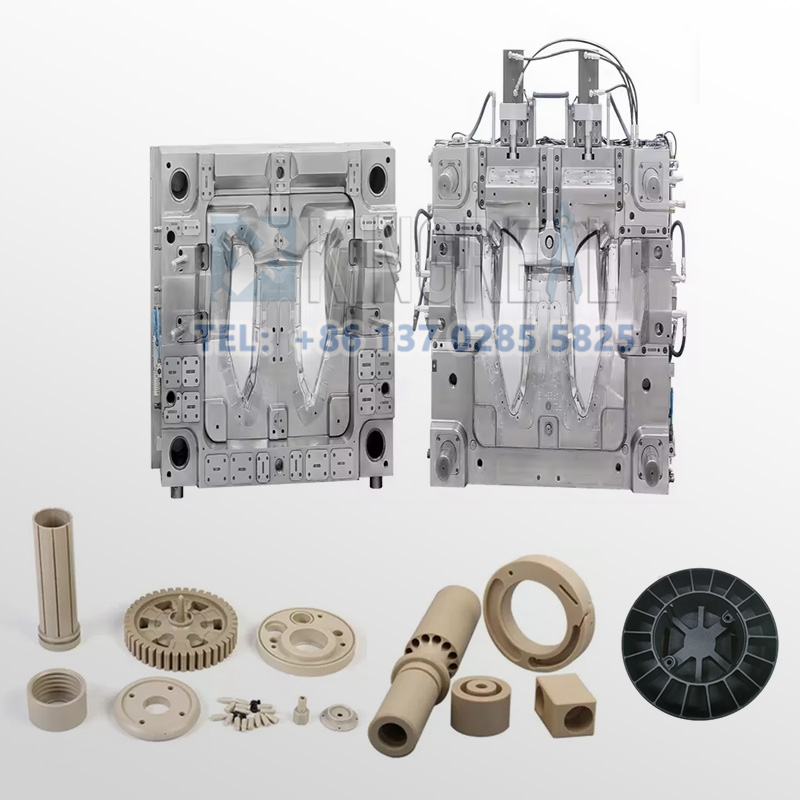

Mostly used to create high-precision plastic components, aviation equipment injection molds are essential tools in contemporary aircraft equipment manufacture. Such aerospace plastic injection molds enable the creation of vital parts in a range of aerospace equipment including window frames, plastic turbine blades, aircraft nose radomes, battery housings, and detonating tubes. Ensuring aircraft performance and safety depends on the manufacture of these elements. KRMOLD will outline the components of aviation equipment injection molds and their significance in aerospace productin in this piece.

1/Components of Aerospace Plastic Injection Mold

There are several essential elements in the design and construction of aviation equipment injection molds, each of which is quite important for the general aerospace plastic injection mold performance and manufacturing efficiency:

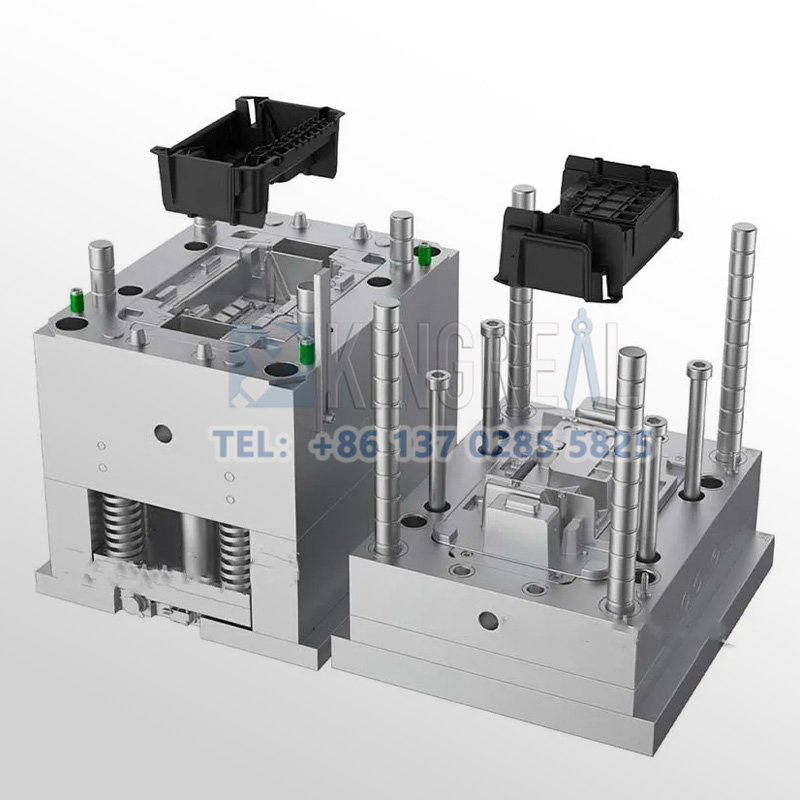

1. Mold Base Plate

Supporting the whole mold framework, aviation equipment injection molds starts with the mold base plate. Stability and longevity of the aerospace plastic injection mold depend on the base plate's material and thickness. During the injection molding process, a premium mold base plate resists the high pressure to guarantee the stability of the aviation equipment injection molds throughout operation.

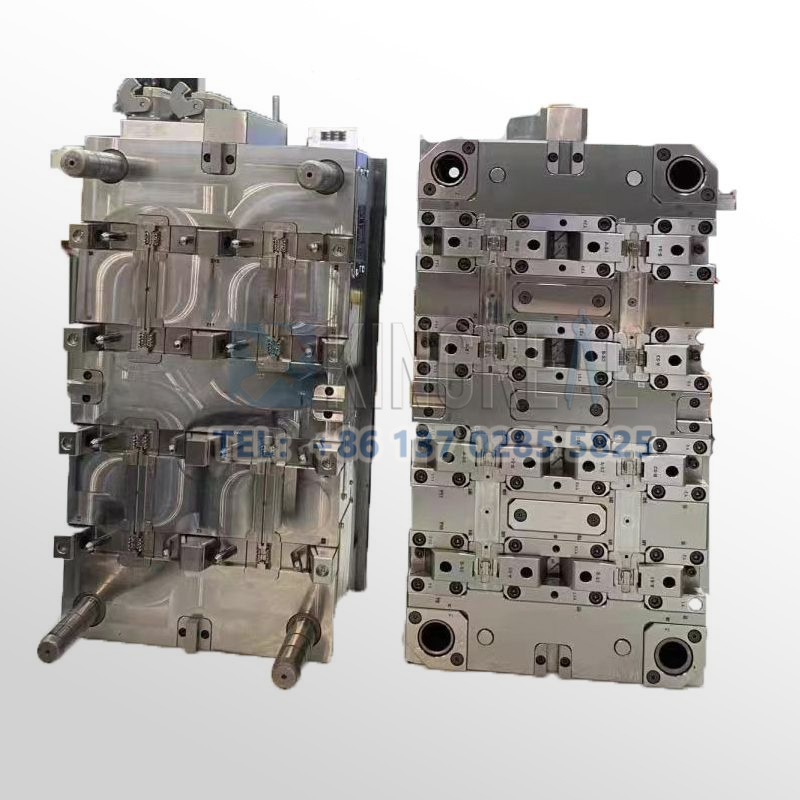

2. Template Plate

Containing several vital functional parts like the product cavity, cooling system, and nozzles, the template plate is the core of an aerospace plastic injection mold. The design of the aviation equipment injection molds template must completely consider its functionality and production efficiency to guarantee fluid molding during injection molding and minimize faults in manufacture.

3. Mold Core

The mold core, used in conjunction with the aerospace plastic injection mold template, is a key component in product manufacturing. Its design determines the shape and dimensions of the final product, thus requiring consideration of the stringent tolerances and precision requirements of aerospace components. High-strength alloys are typically used for the mold core to withstand the high temperatures and pressures of injection molding.

4. System Clamps System

Clamps connect and secure the various parts of the aviation equipment injection molds, ensuring that the aerospace plastic injection mold does not shift or loosen during injection molding. The clamps must be designed to ensure strength and stability to meet the high requirements of aviation equipment injection molds.

5. Mold Core

Inside the mold core, the mold core produces the holes and internal features in the product. To get the intended functional qualities in the finished product, the design and construction of the mold core must guarantee accuracy. Often needing wear-resistant and corrosion-resistant materials, the selection of mold core material is just as critical.

6. Guide Pillars and Bushings

Guide pillars and bushings are crucial components in aerospace plastic injection molds, guiding the aviation equipment injection molds’ position during injection and mold opening. These components effectively prevent interference and damage during operation, thereby improving production efficiency and product quality.

7. Cutting Plate

Mounted on the mold platen, the cutting plate houses the nozzle of the injection molding machine, therefore allowing plastic material to enter the aerospace plastic injection mold. To guarantee fluid passage of plastic into the mold core and cavity during injection, the cutting plate's shape has to match the nozzle of the injection molding machine.

8. Mold Gate

The plastic material passes the mold core and cavity via the mold gate, which joins the injection molding machine to the aerospace plastic injection molds. The design of the gate affects flowability and molding quality during injection, therefore calling for exact calculations and optimal design.

9. Injection Pin Bushing

The injection pin bushing guides the injection pins and determines the timing and location of plastic entry into the mold core. This component's design must consider the flow characteristics during injection to ensure uniform plastic distribution within the mold core.

10. Push Rod

The push rod is used to eject molded parts, preventing them from getting stuck in the aerospace plastic injection mold. The design of the push rod is closely related to the overall aviation equipment injection molds structure, ensuring it can effectively eject the finished product and reduce downtime during production.

2/Why Choose Aerospace Plastic Injection Mold?

1. Wide Range of Material Choices With aviation equipment injection molds, you can choose from a wide range of materials to manufacture various parts and prototypes for the aerospace industry. Commonly used materials include ABS, PP, and HDPE, which meet the high strength and durability requirements of aerospace components.

2. Lightweight and Strong Materials The lightweight nature of plastic materials is particularly important for the aerospace industry, effectively reducing the overall weight of aircraft and improving fuel efficiency. At the same time, the strength of plastic materials makes finished parts more durable and able to withstand various extreme environments.

3. Precision and Accuracy Aerospace Parts With aerospace plastic injection molds, you can manufacture more precise and accurate aircraft parts. These aviation equipment injection molds provide tight tolerances, allowing parts to fit well with other components and reducing complex finishing processes.

4. High Repeatability and High-Quality Products Aerospace plastic injection molds ensure the production of highly repeatable parts, meaning each part is virtually identical, resulting in a low defect rate. This high-quality product ensures the safety and stability of aerospace equipment during operation. |  |

3/Differences Between Aviation Equipment Injection Molds & Ordinary Injection Molds

| 1. Material Differences Ordinary plastic injection molds typically use common materials such as carbon steel and aluminum alloys, which are relatively inexpensive and sufficient for general industrial production needs. Aviation equipment injection molds, on the other hand, utilize more high-performance materials such as specialty engineering plastics, titanium alloys, and magnesium alloys. While these materials are more expensive, they meet the specific requirements of the aerospace field.

2. Performance Indicator Differences Ordinary plastic injection mold materials have relatively lower performance indicators in terms of strength, high-temperature resistance, and fatigue resistance, making it difficult to meet the stringent requirements of the aerospace industry. Aerospace plastic injection mold materials have significant advantages in these performance indicators and can withstand more extreme working conditions.

3. Processing Technology Differences Due to the special properties of aviation equipment injection molds materials, their processing technology is more complex and stringent. For example, titanium alloys are difficult to process, requiring special processing equipment and methods to ensure processing accuracy and surface quality. The processing technology for ordinary plastic injection mold materials is relatively simple and the cost is also low. |  |