| 1 | Function and Construction of Car Battery Box Injection Mould |

| 2 | Parameters of Car Battery Box Injection Mould |

| 3 | Advantages of Car Battery Box Injection Mould |

| 4 | Key Technical Features of KRMOLD Car Battery Box Injection Mould |

| 5 | Application of Car Battery Box Injection Mould in Automotive Industry |

| 6 | Start Your Automotive Project with KRMOLD |

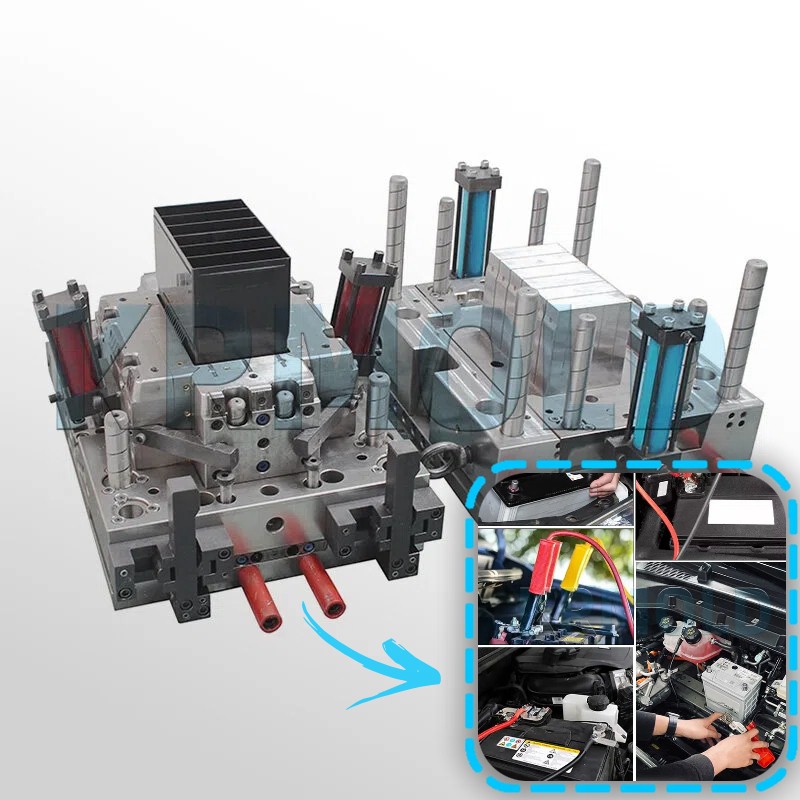

1.Function and Construction of Car Battery Box Injection Mould

Plastic battery case injection mould are specialized equipment used in the injection molding process and are typically produced using polypropylene (PP) or ABS (FR ABS). Because of their outstanding physical qualities and chemical stability, these compounds are much used in the car business. Leading plastic battery case injection mould maker in the sector, KRMOLD chooses H13 steel for plastic battery case molds to guarantee stability and endurance.

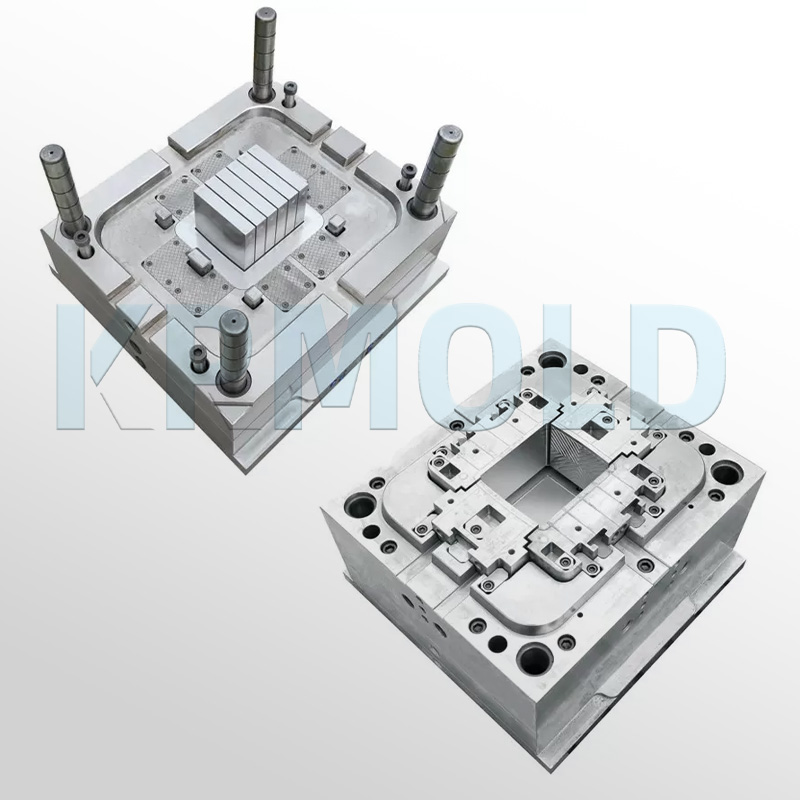

2.Parameters of Car Battery Box Injection Mould

| Mold Name | Plastic battery case injection mould |

| Product Description | 1L Battery Box |

| Mold Cavity | 1 Cavity |

| Mold Material | H13 |

Mold Injection System | 7-Point Hot Runner |

| Mold Ejection System | Ejector Plate |

| Mold Cycle Time | 35 Seconds |

| Mold Lifespan | 1 Million Cycles |

| Mold Features | Excellent Cooling System for Stable Injection |

3.Advantages of Car Battery Box Injection Mould

3.1 Precision and consistency for car battery box injection mould

One major benefit of plastic battery case injection mould is their capacity to guarantee that every plastic piece made adheres to exact standards. This great accuracy guarantees consistency in large-scale manufacturing in addition to reducing flaws. For the car sector, this is vital as even the smallest modification may affect vehicle safety and performance.

3.2 Material diversity for car battery box injection mould

Plastic battery case injection mould offer high material compatibility, accommodating a wide range of materials, from thermoplastics to advanced composites. This versatility allows manufacturers to select the optimal material for their specific needs, whether requiring impact resistance, flexibility, or heat resistance. By choosing this adaptable material, vehicle makers can satisfy performance demands while lowering production costs.

3.3 Cost-effectiveness for car battery box injection mould

In the automotive industry, plastic battery case injection mould enable large-scale production with minimal material waste, making them highly cost-effective. Once the car battery box injection mould are manufactured, unit costs drop significantly, making them an ideal choice for large-scale production in the automotive industry. By optimizing the production process, KRMOLD plastic battery case injection mould achieve higher production efficiency, thereby reducing overall production costs.

4.Key Technical Features of KRMOLD Car Battery Box Injection Mould

KRMOLD is committed to providing customers with high-quality plastic battery case injection mould solutions. The following are key technical features:

4.1

Product molding process analysis

Car battery box injection mould design and manufacturing require in-depth product molding process analysis to ensure a mold lifespan of at least 500,000 cycles. This process involves a comprehensive assessment of the plastic battery case injection mould structure and manufacturing process to ensure the car battery box injection mould’ stability and durability over long-term use.

4.2

Complete car battery box injection mould structure design

KRMOLD can design the complete plastic battery case injection mould structure and machined parts, clearly defining assembly requirements and injection molding process requirements. This capability ensures efficient car battery box injection mould operation and reduces potential production issues.

4.3

Appearance quality control for car battery box injection mould

The plastic battery case injection mould’ appearance quality directly impacts the quality of the final product. KRMOLD ensures plastic battery case injection mould are free of rust, impacts, defects, and other module defects, ensuring the finished plastic parts have excellent appearance quality.

4.4

Car battery box injection mould transportation and documentation

During transportation, plastic battery case injection mould must be secured with locking plates and securely packaged to prevent rust. KRMOLD also provides documentation of consumable parts upon mold delivery to ensure timely replacement and maintenance during use.

5.Application of Car Battery Box Injection Mould in Automotive Industry

Car battery box injection mould are crucial in the automotive industry. With the rise of electric and hybrid vehicles, the demand for battery cases is increasing. Plastic battery cases not only need to support the weight of the batteries but also protect them from external impact and damage during operation.

5.1 Improving vehicle performance Good plastic battery case injection mould can yield premium battery cases that significantly improve the general performance of a car. Plastic battery boxes can more fit the vehicle's design and guarantee battery stability in many different operating circumstances thanks to an improved design.

5.2 Reducing production costs En la producción a gran escala, la eficiencia del molde de inyección de cajas de baterías de automóvil impacta directamente los costos de producción. Al reducir el desperdicio de material y mejorar la eficiencia de producción, los fabricantes de automóviles pueden reducir significativamente los costos generales de producción, manteniendo la calidad del producto.

5.3 Adaptación a los cambios del mercado Con el rápido desarrollo del mercado automotriz, la demanda de vehículos de los consumidores también está en constante evolución. Los moldes de inyección de carcasas de batería de plástico KRMOLD ofrecen una excelente escalabilidad, lo que les permite adaptarse rápidamente a las cambiantes demandas del mercado. Esta flexibilidad permite a los fabricantes de automóviles responder con mayor rapidez a los cambios del mercado y ofrecer a los consumidores productos más competitivos. |  |

6. Inicie su proyecto automotriz con KRMOLD

Ya sea que esté creando un prototipo de una nueva pieza o ampliando la producción, KRMOLD ofrece soluciones personalizadasMolde de inyección para caja de batería de cocheSoluciones para la industria automotriz. Aprovechando las avanzadas capacidades de fabricación de KRMOLD, puede obtener moldes de inyección de carcasas de batería de plástico de alta calidad y producir rápidamente piezas de plástico de alta precisión para satisfacer las diversas necesidades de la industria automotriz.

El equipo de KRMOLD le proporcionará un presupuesto personalizado según sus necesidades específicas, para que pueda dar el primer paso con confianza al iniciar su proyecto. Ya sea la selección de materiales, el diseño de moldes de inyección para cajas de baterías de automóvil o los procesos de producción, KRMOLD le brindará un servicio profesional y eficiente para garantizar el éxito de su proyecto de fabricación automotriz.