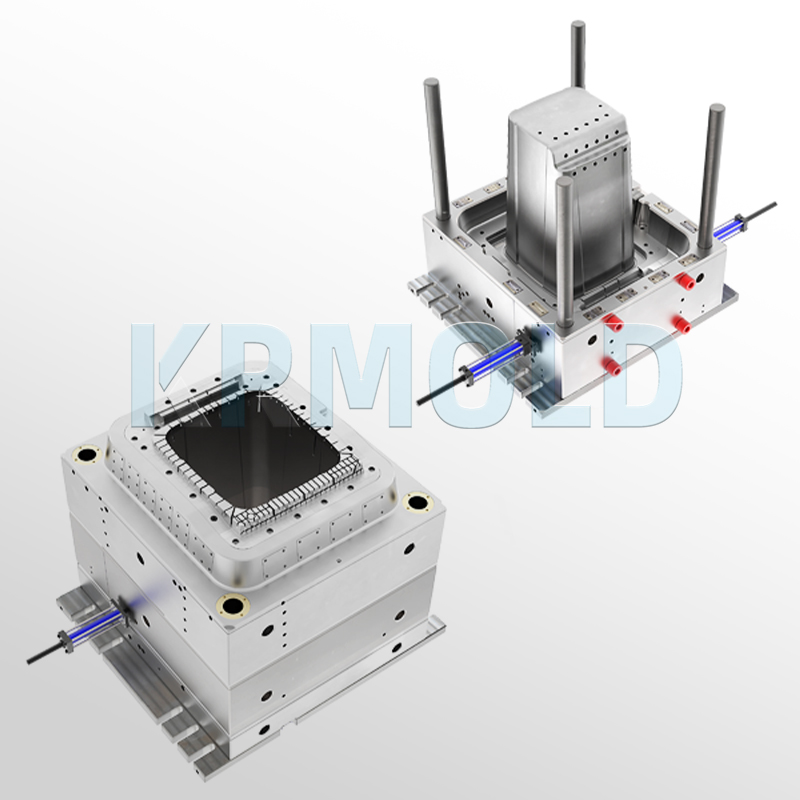

| Waste bin injection molds are specifically used to produce various types of garbage cans, including those with different capacities (32L, 45L, 60L, 80L, 120L, 240L, etc.) and different functions (foot-operated, vehicle-mountable, household multi-tiered, medical, and general-purpose). The large-scale, precise production of garbage cans using garbage bin injection mould makes them ubiquitous in daily life, contributing to environmental sanitation, promoting resource recycling, and reducing the spread of disease. The quality of the waste bin injection mold directly affects the performance and market competitiveness of the garbage cans. |  |

Key Quality Points of Garbage Can Injection Mould

1. Short injection molding cycle and high output per unit time

Injection molding technology is widely used in the manufacturing of garbage cans due to its fast production cycle and high efficiency. By analyzing the temperature distribution during the molding process using CAE software, the cooling system can be enhanced in areas with the highest temperatures. This not only effectively shortens the cooling time but also accelerates the overall cycle, improving production efficiency per unit time.

2. Strong molding system stability and high yield rate

The design of garbage bin injection mould must focus on the rationality of the runner system. A well-designed runner system not only ensures uniform material flow but also effectively improves the yield rate. Furthermore, the use of German-imported hot runner heating elements ensures more balanced and stable heating, contributing to a higher product pass rate and guaranteeing the economic benefits of the manufacturing company.

3. Uniform wall thickness, no eccentricity, and long mold life

In the production of garbage cans, the uniformity of the product's wall thickness is crucial. The assembly accuracy and processing dimensional accuracy of the waste bin injection mold are directly related to this. In addition, a reasonable waste bin injection mold clamping and guiding mechanism design is one of the important factors in improving mold life. Ensuring the precise assembly of all parts of the garbage bin injection mould can effectively prevent eccentricity and uneven wall thickness in the finished product, thereby extending the waste bin injection mold's service life.

4. Suitable for low MFI plastic injection molding, resulting in durable products

Low MFI plastics are widely used in the production of garbage cans due to their toughness, impact resistance, and aging resistance. The design of the garbage bin injection mould must have good strength, be able to withstand the pressure during the molding process, and maintain a reasonable balance of forces. Such waste bin injection molds not only meet production needs but also ensure the durability of the final product.

How to Better Control Garbage Bin Injection Mould Quality?

1. Waste bin injection mold assembly Garbage bin injection mould assembly is a crucial step in the production of waste bin injection molds. Just like assembling a complex machine, the installation of every component and every screw must be precise. Any error can not only lead to product defects but also potentially cause complete garbage bin injection mould damage. Therefore, during the assembly process, special attention must be paid to ensuring the cleanliness of the waste bin injection mold, especially the water channels and screw holes, which need to be thoroughly cleaned to prevent damage from foreign objects such as metal shavings.

2. Cooling water channels for waste bin injection molds The quality of the cooling system design directly affects the production efficiency of the garbage bin injection mould. In mass production, if the waste bin injection mold temperature rises, it will seriously affect the molding effect, and may even lead to garbage bin injection mould deformation or failure. A good cooling water channel design should consider factors such as the layout, diameter, and density of the water channels to ensure a balance between cooling effect and production efficiency.

3. Waste bin injection mold maintenance Garbage bin injection mould maintenance and upkeep are fundamental to ensuring the long-term use of waste bin injection molds. Just like a car, a waste bin injection mold will inevitably suffer functional damage if not maintained for a long time. Therefore, after each operation, the garbage bin injection mould should be thoroughly maintained, especially the rust prevention of the molding parts. Since the waste bin injection mold may come into contact with moisture during operation, it is essential to ensure the garbage bin injection mould is dry before applying a layer of anti-rust oil to protect it. |  |

KRMOLD Waste Bin Injection Mold Manufacturing Solution

KRMOLD is committed to providing customers with high-quality garbage bin injection mould manufacturing solutions. Based on customer needs, KRMOLD can transform customer ideas into detailed product design drawings, ensuring the rationality of the waste bin injection mold design. During the garbage bin injection mould manufacturing process, KRMOLD strictly controls production quality and management processes, ensuring that every step meets the standards. In addition, KRMOLD provides detailed maintenance manuals and sufficient spare parts after waste bin injection mold shipment to ensure the continuous and efficient operation of the garbage bin injection mould. At the same time, KRMOLD also provides timely after-sales service to ensure that all customer needs are met satisfactorily.

The quality of waste bin injection molds directly affects the performance and market pricing of garbage cans. Through reasonable design, meticulous assembly, good cooling water channels, and regular maintenance, the quality of the garbage bin injection mould can be effectively controlled. With its professional technical team and equipment, KRMOLD can provide customers with high-quality waste bin injection mold manufacturing solutions. If you have a need to purchase high-quality garbage bin injection mould, please contact KRMOLD immediately for detailed quotations and service information.